◆ The use of visual inspection, replace the visual inspection that is not stable (optional)

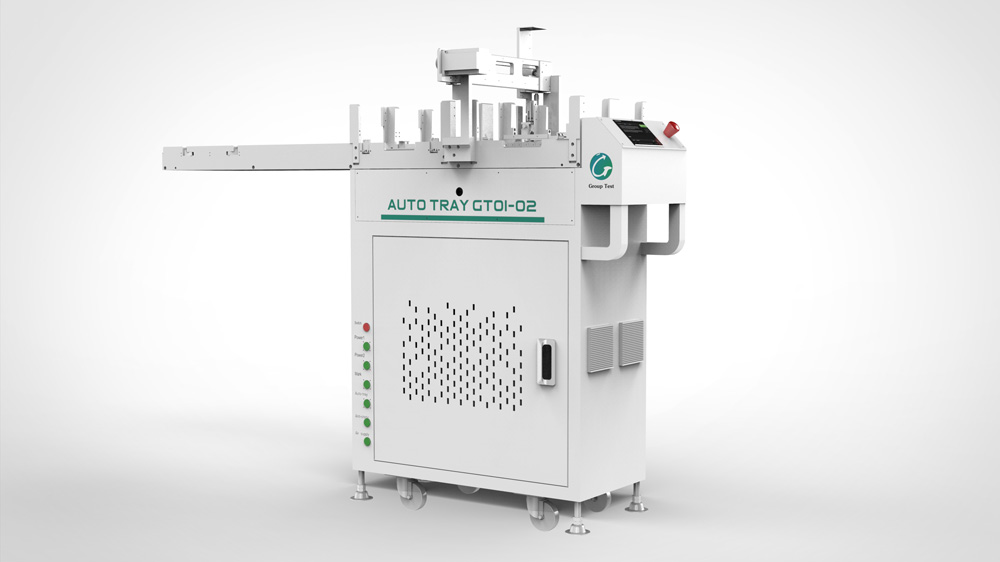

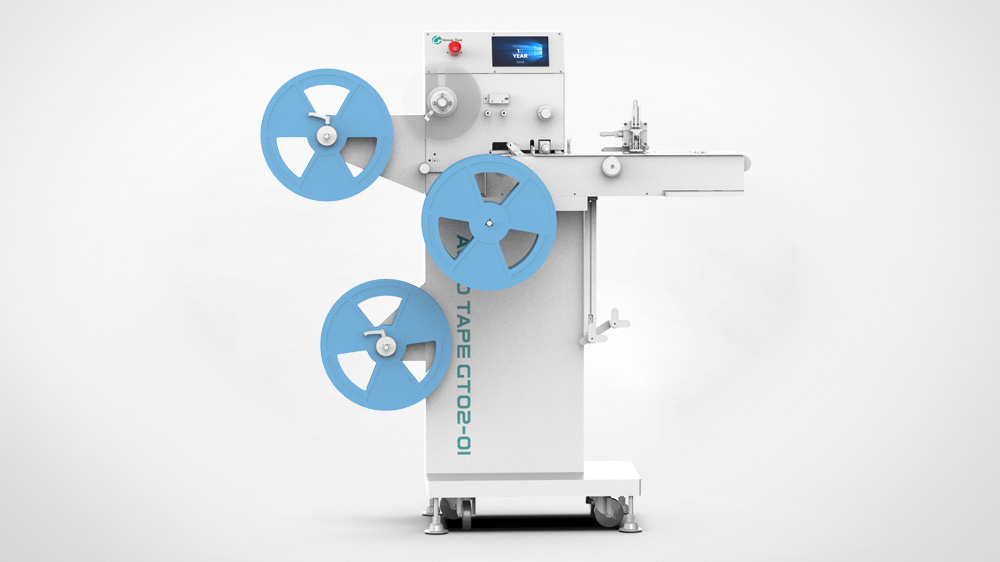

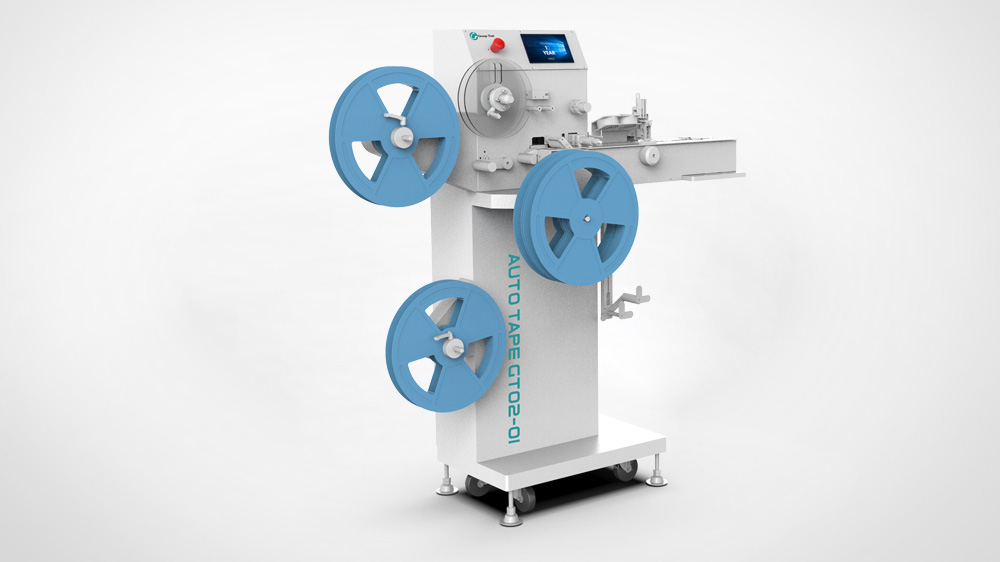

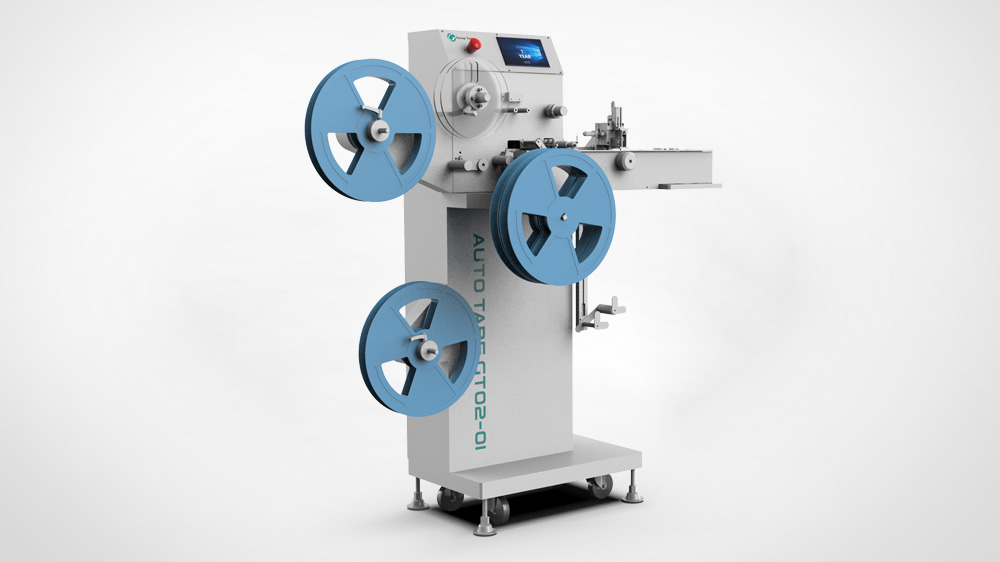

◆ The device is a fully automatic burner plug-in equipment for chip sticking (heat sealing), instead of artificial

◆ Support a variety of IC packaging of the Zhuan (heat sealing)

◆ Material bandwidth 8 ~ 32mm

◆ Optional self-adhesive or heat-sealed type

◆ Support ink print module, laser print module (optional)

◆ Simplified Chinese interface, simple operation

◆ Equipped with inspection module

◆ High flexibility, for different IC, adjust the light source and optical function, to achieve the best test

◆ Optional black and white camera or color camera

◆ Reduce the involvement of operating personnel, to maximize production capacity, quality optimization

◆ Secondary re-examination function

New generation of discharge device

◆ After the material is burned, it is placed directly into the tape, allowing the device to achieve the highest performance

◆ The marking device is at the front of the membrane of the machine so as not to affect the discharge of the equipment

◆ Ink printing can support RBI, digital, English letters a number of functions

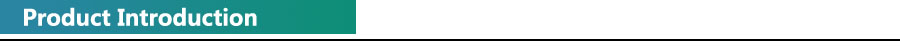

◆ IC code is printed inspection(MARK)

◆ IC orientation test(Orientaion)

◆ IC marking quality inspection(Dot)

◆ IC pin test(Scan)

◆ Tape sealing test(Seal)

◆ Stacking test(Stack)

◆ Empty material detection(Empty)

Support IC package type | All reel packaging |

IC move the module | Servo stepper motor |

Print module | Ink print module: single point (0.8mm ~ 2.0mm) Single English (2mm ~ 3mm) Single digit (2mm ~ 3mm) Laser Print Module: |

Image view | Phase device: camera: 1.3 million pixel camera |

Air pressure source | 0.6Mpa,55L/min |

power supply | Input voltage: 220 ~ 240VAC single phase Input frequency: 50 ~ 60HZ Rated power: 1.3KVA |

Return

Return